Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

Slim Aluminum Profile Manufacturer: Leading the Industry in Innovation and Quality

The manufacturing industry has seen a significant transformation with the advent of slim aluminum profiles. These lightweight, durable, and versatile materials have become indispensable in various applications, from construction to electronics. In this comprehensive blog, we will delve into the world of slim aluminum profile manufacturers, exploring their significance, applications, and the factors that make a top-tier manufacturer stand out. By the end of this article, you'll have a clear understanding of why partnering with a reputable slim aluminum profile manufacturer is crucial for your business.

Introduction to Slim Aluminum Profiles

What are Slim Aluminum Profiles?

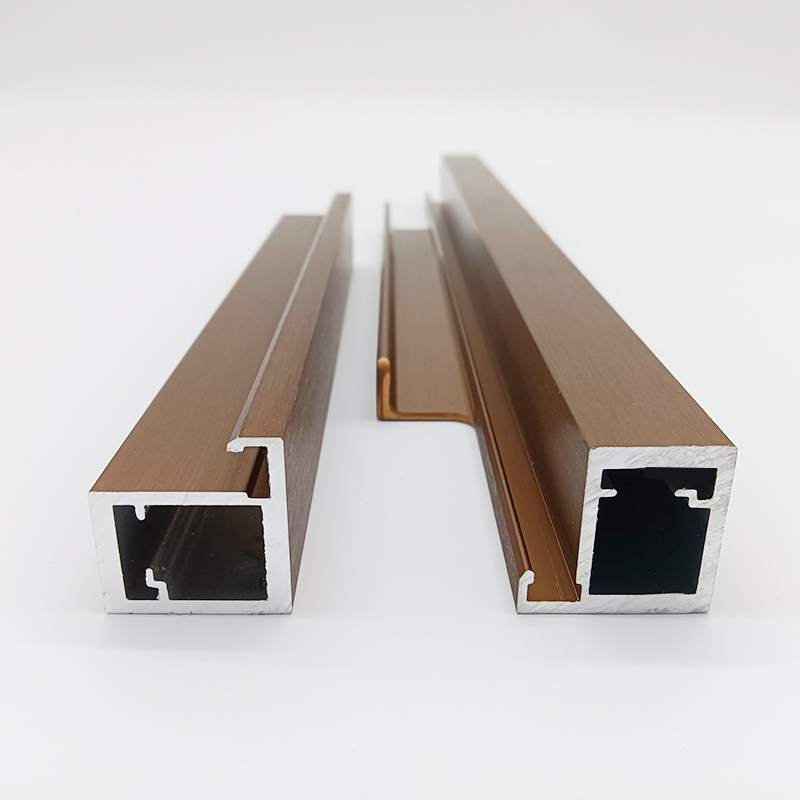

Slim aluminum profiles are extruded aluminum sections characterized by their narrow and sleek dimensions. These profiles are designed to provide structural integrity and aesthetic appeal while minimizing weight. The use of aluminum in these profiles offers several advantages, including corrosion resistance, high strength-to-weight ratio, and recyclability.

Applications of Slim Aluminum Profiles

Slim aluminum profiles find applications in numerous industries, including:

Construction: Used in windows, doors, curtain walls, and facade systems.

Electronics: Essential in the manufacturing of heat sinks, enclosures, and frames for electronic devices.

Automotive: Applied in vehicle frames, roof rails, and trim components.

Aerospace: Used in aircraft structures and components due to their lightweight and strong properties.

Furniture: Commonly used in modern furniture designs for their sleek appearance and durability.

The Role of a Slim Aluminum Profile Manufacturer

Importance of Quality Manufacturing

The quality of slim aluminum profiles is paramount to their performance in various applications. A reputable manufacturer employs advanced extrusion technologies and rigorous quality control processes to ensure their products meet industry standards and customer specifications.

Innovative Design and Customization

Leading manufacturers offer innovative design solutions and customization options to meet the unique needs of their clients. This includes the ability to produce profiles in various shapes, sizes, and finishes, catering to specific project requirements.

Sustainable Manufacturing Practices

Sustainability is a growing concern in the manufacturing industry. A top manufacturer adopts eco-friendly practices, such as using recycled aluminum and implementing energy-efficient production methods, to minimize their environmental footprint.

Factors to Consider When Choosing a Slim Aluminum Profile Manufacturer

Experience and Expertise

The experience and expertise of a manufacturer play a crucial role in the quality and reliability of their products. Look for manufacturers with a proven track record in the industry and a portfolio of successful projects.

Technological Capabilities

Advanced technological capabilities are essential for producing high-quality slim aluminum profiles. Manufacturers equipped with state-of-the-art extrusion machines, CNC machining centers, and surface finishing equipment can deliver superior products.

Quality Assurance

A robust quality assurance system ensures that every profile meets the required standards and specifications. Reputable manufacturers conduct thorough inspections and tests, including dimensional checks, mechanical testing, and surface finish evaluations.

Customer Support and Service

Exceptional customer support and service are vital for a smooth manufacturing process. Choose a manufacturer that offers comprehensive support, from initial design consultation to post-delivery assistance, ensuring your needs are met at every stage.

Case Studies: Success Stories of Leading Slim Aluminum Profile Manufacturers

Zhongwang Holdings: Revolutionizing the Construction Industry

Zhongwang Holdings has been at the forefront of the construction industry, providing slim aluminum profiles for various high-profile projects. Their innovative designs and commitment to quality have earned them a reputation as a reliable partner for architects and builders. Zhongwang's profiles are known for their durability and aesthetic appeal, making them a preferred choice for modern construction projects. Their work on landmark buildings such as skyscrapers and commercial complexes showcases their ability to deliver top-notch aluminum solutions.

Hydro Extrusions: Advancing Electronics with Precision

Hydro Extrusions specializes in producing slim aluminum profiles for the electronics industry. Their precision engineering and customization capabilities have enabled them to supply profiles for leading electronic device manufacturers, contributing to the development of cutting-edge technology. Hydro's profiles are used in a variety of electronic applications, including heat sinks, enclosures, and structural components for high-tech devices. Their commitment to innovation and quality has made them a key player in the electronics sector, helping to drive advancements in technology.

Constellium: Driving Automotive Innovation

Constellium has made significant contributions to the automotive industry with their lightweight and durable aluminum profiles. Their expertise in designing and manufacturing profiles for automotive applications has resulted in improved vehicle performance and efficiency. Constellium's aluminum solutions are utilized in various components, from vehicle frames to intricate trim parts, enhancing the overall design and functionality of modern automobiles. Their collaboration with major automotive manufacturers highlights their role in pushing the boundaries of automotive innovation.

The Future of Slim Aluminum Profile Manufacturing

Technological Advancements

The future of slim aluminum profile manufacturing lies in continuous technological advancements. Innovations in extrusion techniques, material science, and automation will drive the industry forward, enabling manufacturers to produce even more precise and high-performance profiles.

Sustainable Practices

As environmental concerns continue to rise, the industry will see a stronger emphasis on sustainable manufacturing practices. Slim aluminum profile manufacturers will adopt greener production methods, reducing their carbon footprint and promoting the use of recycled materials.

Expanded Applications

The versatility of slim aluminum profiles will lead to their expanded use in new and emerging industries. From renewable energy solutions to advanced transportation systems, these profiles will play a crucial role in shaping the future of various sectors.

Conclusion

Partnering with a reputable slim aluminum profile manufacturer is essential for ensuring the success of your projects. By considering factors such as experience, technological capabilities, quality assurance, and customer support, you can make an informed decision and benefit from high-quality, customized profiles.

As the industry continues to evolve, staying abreast of the latest trends and innovations will help you leverage the full potential of slim aluminum profiles. Whether you're in construction, electronics, automotive, or any other industry, these profiles offer unmatched benefits that can enhance the performance, aesthetics, and sustainability of your products.