Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

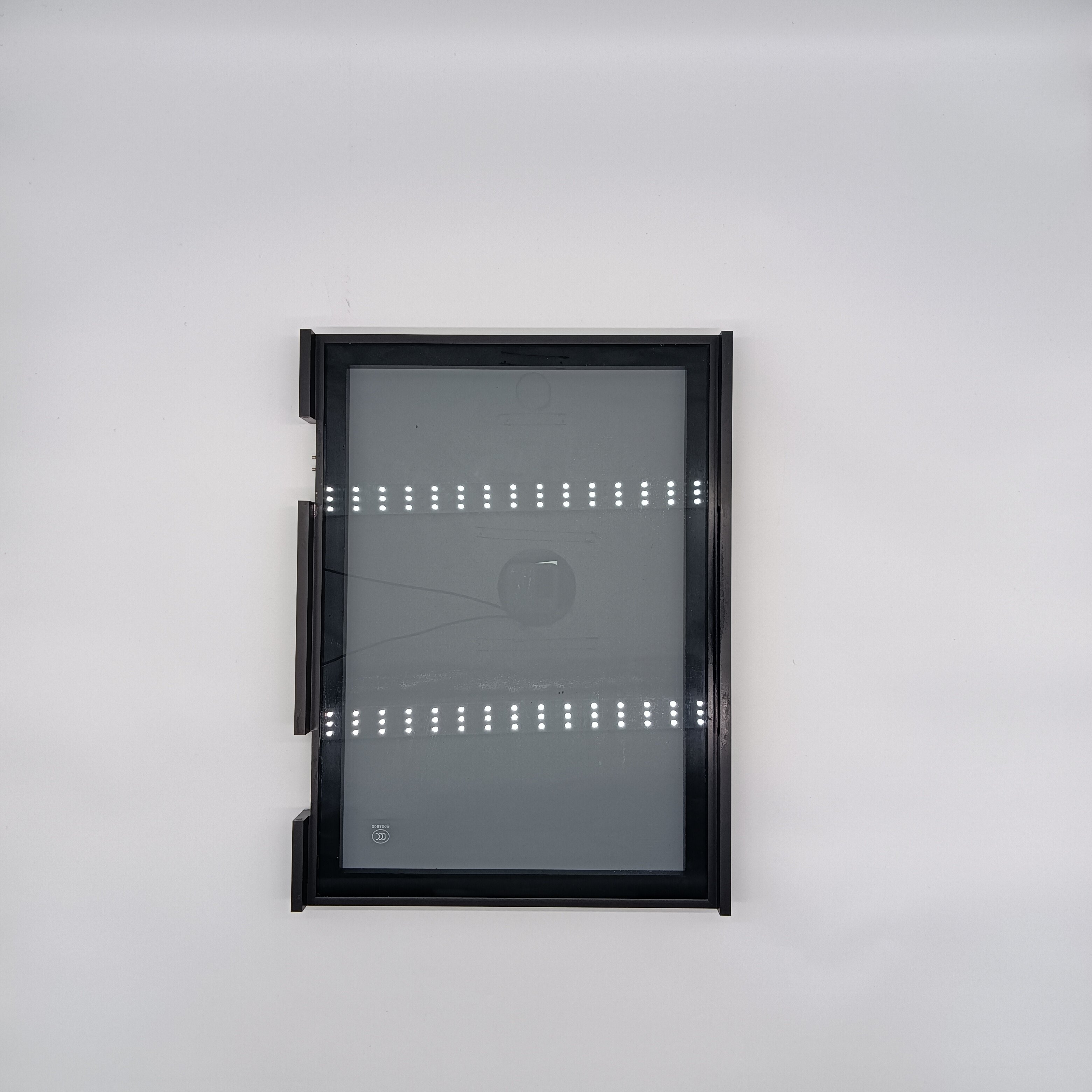

Soft close pivot Hinged framed Cabinet door Aluminum Frame for Cabinet Door Glass

Cabinet doors are some of the most-used areas of your home. You also want your house to be a showcase, and cleaning up after your kids or guests can be one of the hardest parts. So it’s no wonder that many homeowners focus so much on cabinet door styles that are easy to clean, but not at all difficult when they’re properly cared for.

Product Description of Cabinet Doors

A cabinet door is an important aspect of any cabinet, and it is essential that it functions properly. One type of cabinet door that has gained popularity in recent times is the soft close pivot hinged framed cabinet door.

Product Features of Cabinet Doors

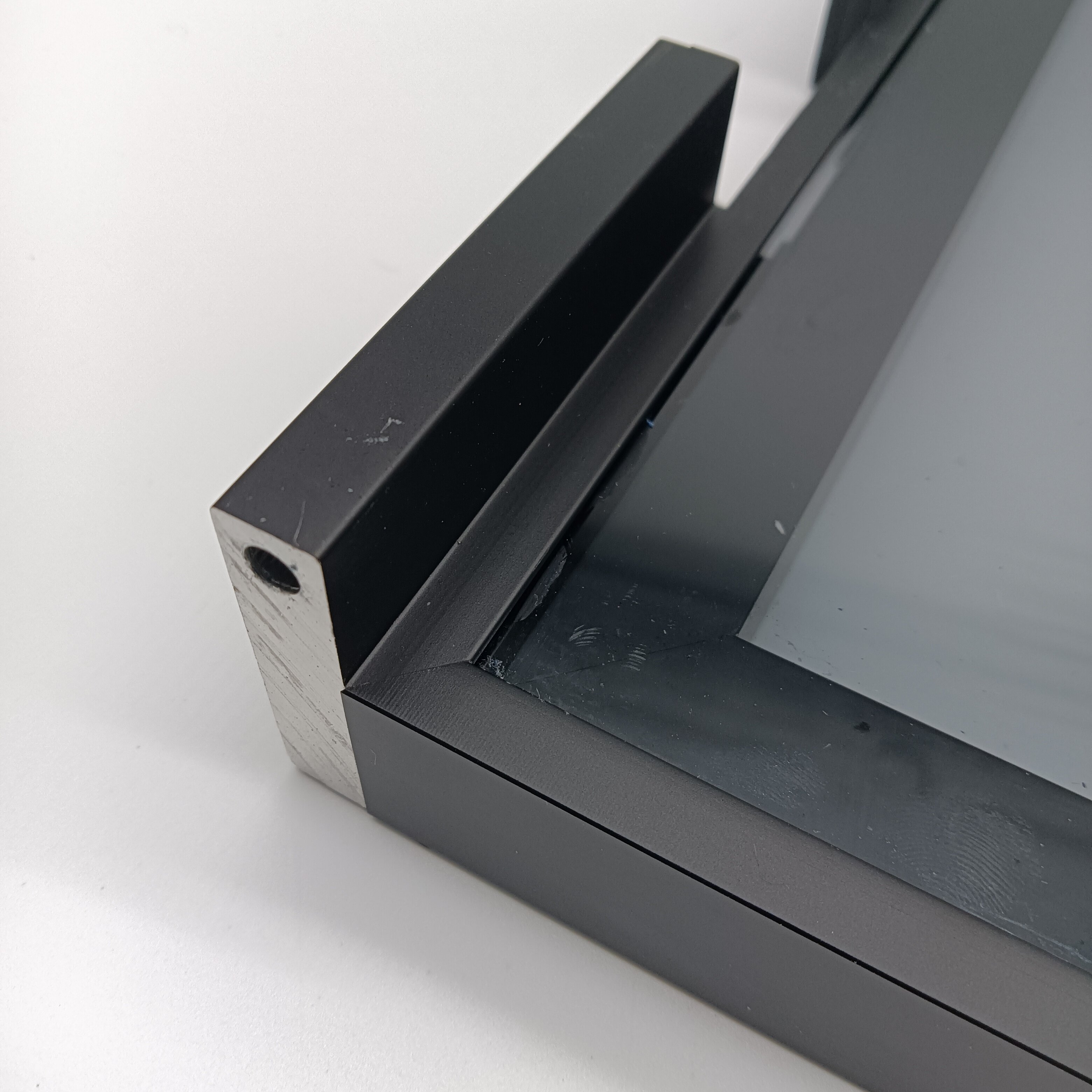

One of the key factors that sets us apart from our competitors is our use of A0 aluminium ingots as raw materials. We also use the most commonly used 6063-T5 and 6061-T6 aluminium alloys that comply with national standards GB/T5237. This ensures that all our products are of the highest quality.

Product Name

Soft-close pivot hinged-framed cabinet door profile

Material

6063-T5 aluminium

Features

European standard

MOQ

There is no minimum order quantity for our stock product.

Colours

Black/Gold/Grey/Customised

Packaging

Plastic bag, carton, and pallet

How to Install Door Hinges

- Steps to install hinges:

- Determine hinge location on the door frame: most doors need at least two hinges, 18cm from the top of the frame and 28cm from the bottom of the frame. Mark these distances on the door frame and the door to be installed.

- Trace the hinges on the door and jamb with a pencil. Make sure the hinge is aligned with the door and frame before continuing.

- Use a chisel and hammer to dig out the hinge shape in the door frame. Only chisel the part circled by the outline, and the depth should be based on the mark.

- Attach the hinges to the slotted holes in the door frame. Mark the screw locations on the door frame and door with a pencil. Remove the hinges.

- Use a power drill or screwdriver to drill small pilot holes at the screw locations on the door frame. Hammer the screws in first to ensure they don't come off accidentally. Use a screw sleeve to drill the screw vertically into the wood.

- Put the hinges in place and fasten them to the door frame and door with a drill or screwdriver.

- Install the door on the door frame. Check that the door opens and closes correctly. The door hinges are now ready.

Our factory was established in 2008, covers an area of 56,368 square meters, has 176 employees. With 5 aluminum production lines, 20 CNC machining centers, 2 powder coating lines, several anodizing tanks, Polishing, brushing and sand blasting equipments, Well-established packaging and quality inspection system, our annual output of aluminum is 15000 tons, and more than 20,000 sets of finished products. We can satisfy your demands quickly from our stock or produce your own design. We do ODM and OEM.

We choose A0 degree aluminum ingot as raw material.

The most used 6063-T5 and 6061-T6 aluminum alloy comply with national standards GB/T5237.

We do extruding with designed moulds to get different shape of profiles.

The strength and toughness of the profiles are ensured by aging treatments.

Surface treatment like powder coating, anodizing and electrophosis are required to protect the profile and get good-looking surface.

We do offer machining services like milling, drilling, bending, threading, etc.

All products will be inspected strictly before packing.

After you place your order, we will check again and suggest you the best packaging method based on different shapes of products (including but not limited to kraft paper packaging/bubble wrap/wooden box packaging).

We provide different packages for different products to make sure the goods can stay good during long-time shipping. And we can do customization according to your requirement.

Usually we will use kraft paper, bubble wrap, plastic protective film, cartons, wood crate and pallet, ect.

Usually we need 15-45 days for production, and we would communicate with customers about all details for shipping a week earlier before goods are ready.

Either you have shipping agents or not, we can assist you to ship the goods and provide you documents for custom clearance. And door to door shipping is also available.