Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

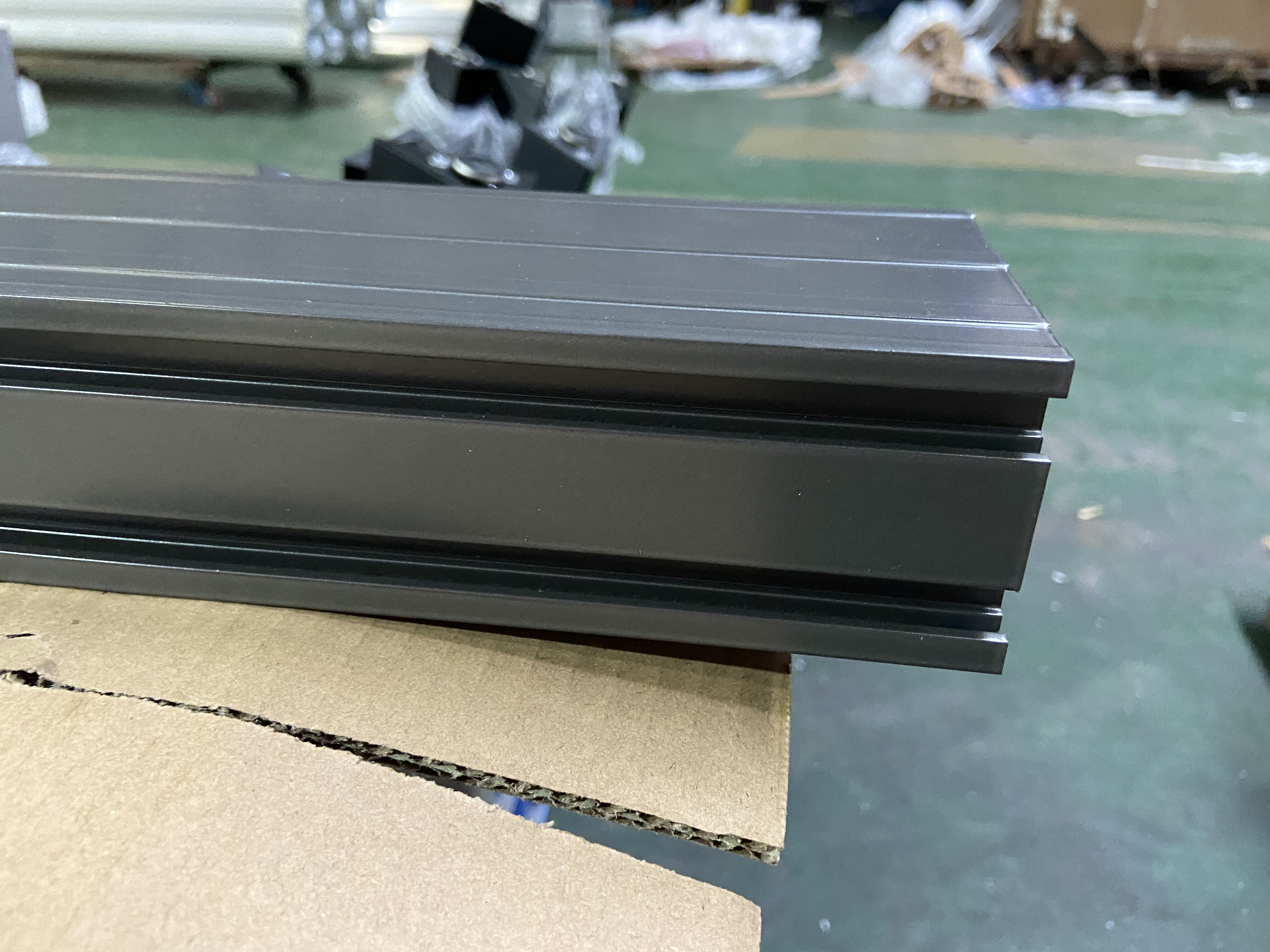

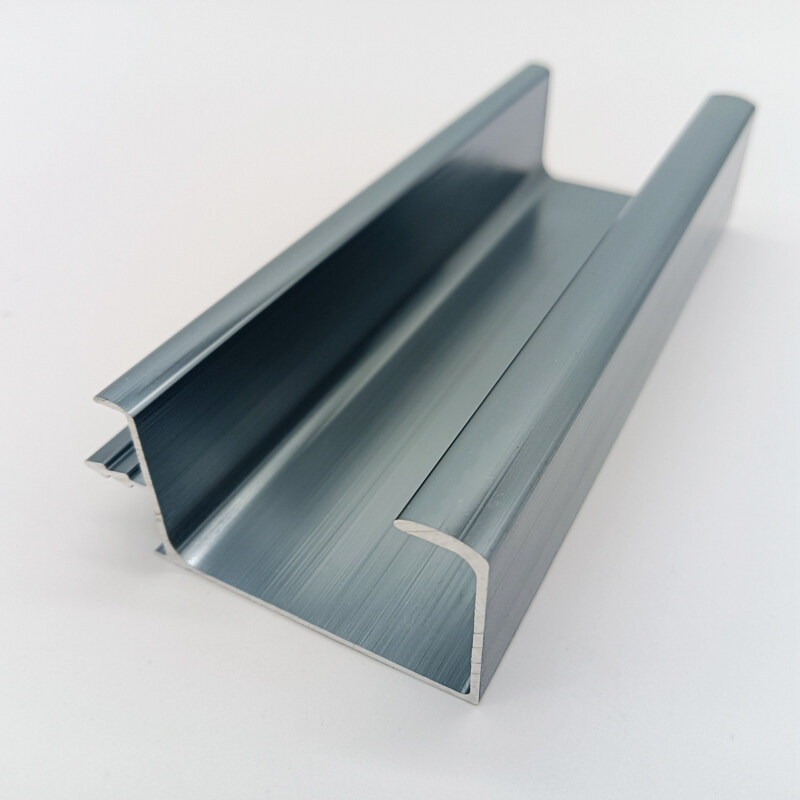

Square comers table leg Italian Stainless Steel Leg Rock Plate table Modern Sintered Stone Dining table frame

The tough anti-rust powder-coated metal table leg will lend some on-trend industrial cred to any ensemble. The design is durable and reliable, while the lightweight construction and smooth rolling casters make it easy to move when needed. This versatile piece can be used anywhere; at home, in the office, or the dorm room.

Product Description of a Metal Dining Table Leg

Table legs are the pillars that hold up the tabletop and determine the stability of the entire table. Square-cornered table legs are one of the most popular types of table legs.

Product Features and Advantages of A Metal Dining Table Leg

Anti-rust aluminium alloy legs

The tough anti-rust powder-coated metal table leg will lend some on-trend industrial cred to any ensemble. Max Weight Capacity: 200 KG

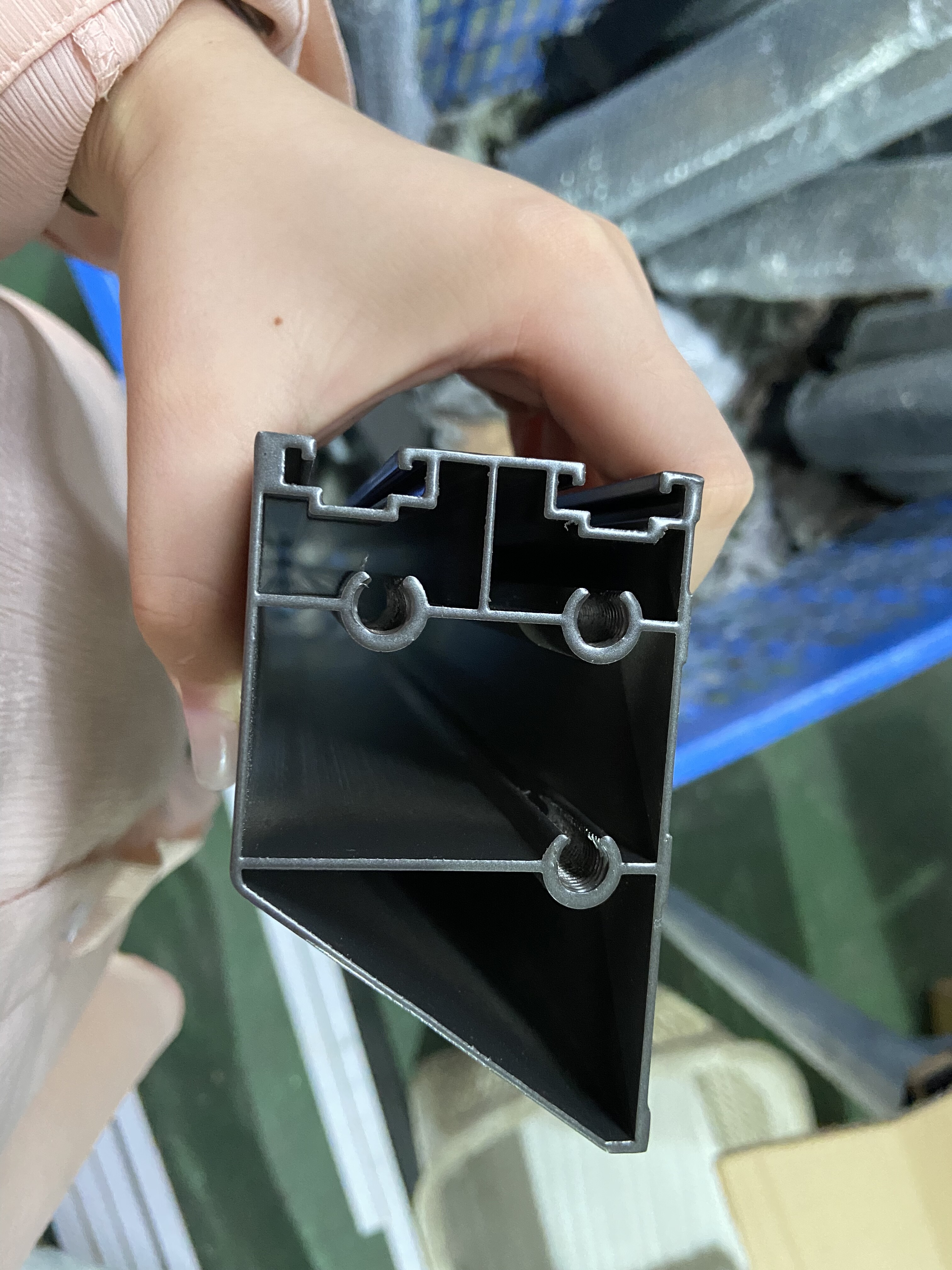

75-mm-thickness iron tube

Made of premium aluminium alloy with a tube thickness of 75mm, the black table leg is durable and able to withstand robust use.

Pre-drilled Holes

Pre-drilled holes at the top allow you to easily attach the leg to the tabletop. (Note: Neither tabletop nor screws are included.)

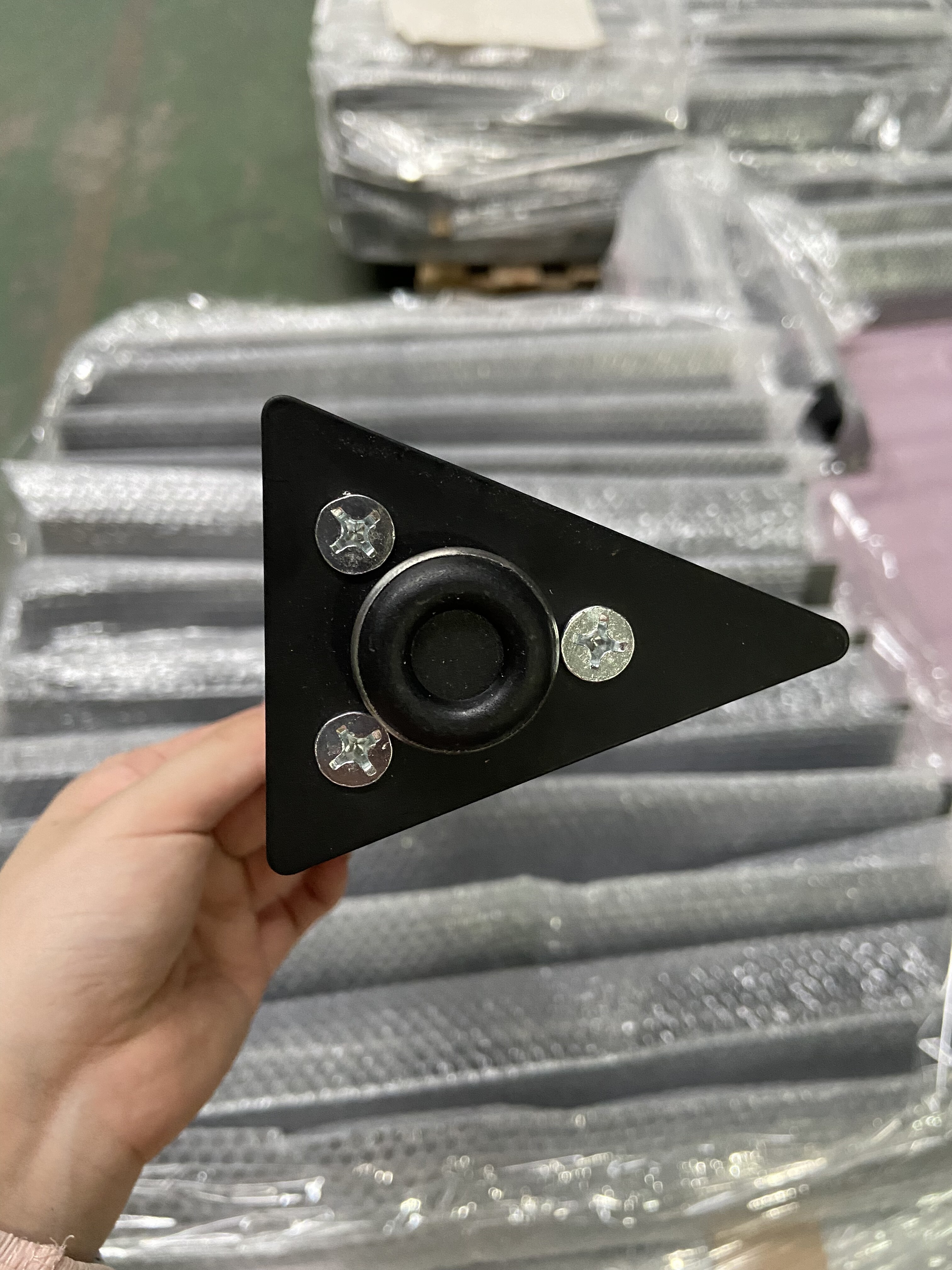

Bonus non-slip pads

A non-slip pad can be fixed to each leg for a firmer stand and to prevent scratches on your pristine floor.

Versatile DIY Use

Overall Dimensions: 40cm (H) x 30cm (L). Attach the rectangular table legs to writing desks, coffee tables, dining tables, benches, or any kind of furniture that would be enhanced with some unique support.

How do I choose table legs?

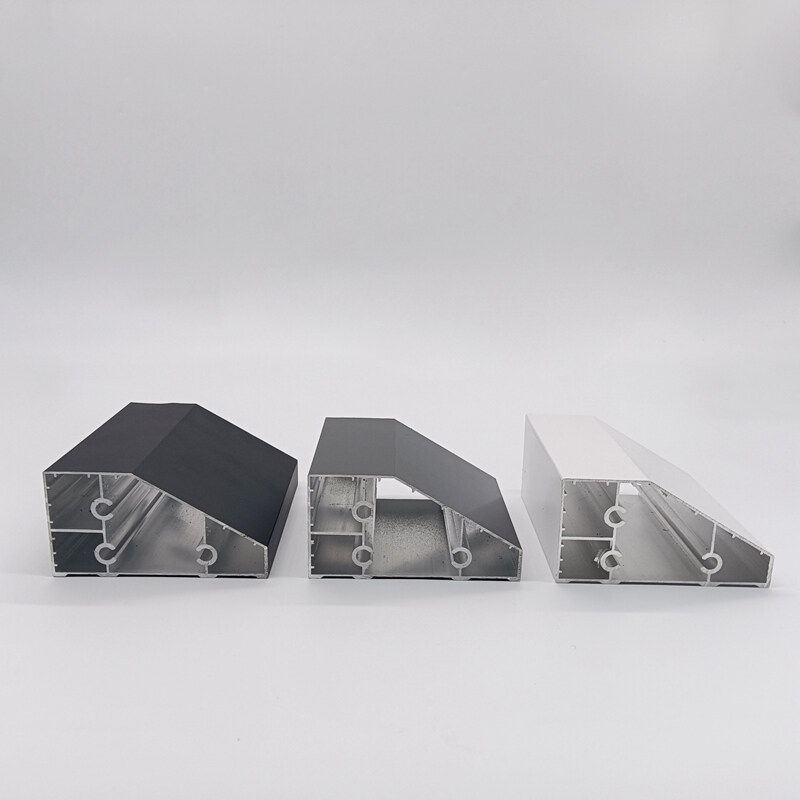

- Choosing Table Legs: With the increasing availability of table leg materials, it can be overwhelming to decide what to choose. Stainless steel, aluminum alloy, and cast iron are durable and resistant to rust, but more expensive. Steel is cheaper but less durable. Stainless steel and aluminum are ideal for modern cafes, while cast iron is suitable for retro-style establishments.

- Checking the Thickness: It is important to check the thickness of the table legs to ensure the product is not compromised and the price is fair. Some manufacturers may reduce the thickness of the material to reduce costs, so be wary of this.

- Ensuring Stability: Stability is key when choosing table legs to avoid accidents. Test the balance and stability of the legs before purchasing to ensure it is suitable for use.

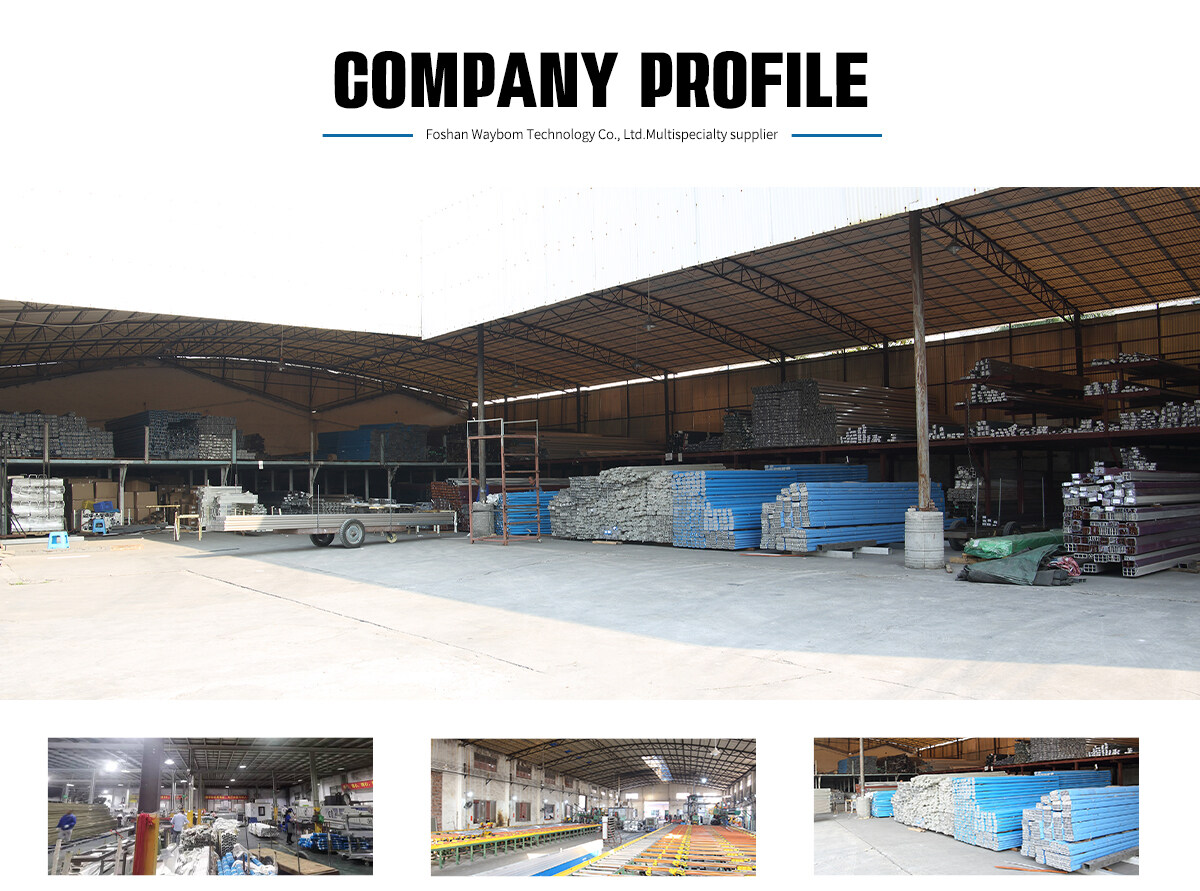

Our factory was established in 2008, covers an area of 56,368 square meters, has 176 employees. With 5 aluminum production lines, 20 CNC machining centers, 2 powder coating lines, several anodizing tanks, Polishing, brushing and sand blasting equipments, Well-established packaging and quality inspection system, our annual output of aluminum is 15000 tons, and more than 20,000 sets of finished products. We can satisfy your demands quickly from our stock or produce your own design. We do ODM and OEM.

We choose A0 degree aluminum ingot as raw material.

The most used 6063-T5 and 6061-T6 aluminum alloy comply with national standards GB/T5237.

We do extruding with designed moulds to get different shape of profiles.

The strength and toughness of the profiles are ensured by aging treatments.

Surface treatment like powder coating, anodizing and electrophosis are required to protect the profile and get good-looking surface.

We do offer machining services like milling, drilling, bending, threading, etc.

All products will be inspected strictly before packing.

After you place your order, we will check again and suggest you the best packaging method based on different shapes of products (including but not limited to kraft paper packaging/bubble wrap/wooden box packaging).

We provide different packages for different products to make sure the goods can stay good during long-time shipping. And we can do customization according to your requirement.

Usually we will use kraft paper, bubble wrap, plastic protective film, cartons, wood crate and pallet, ect.

Usually we need 15-45 days for production, and we would communicate with customers about all details for shipping a week earlier before goods are ready.

Either you have shipping agents or not, we can assist you to ship the goods and provide you documents for custom clearance. And door to door shipping is also available.