Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

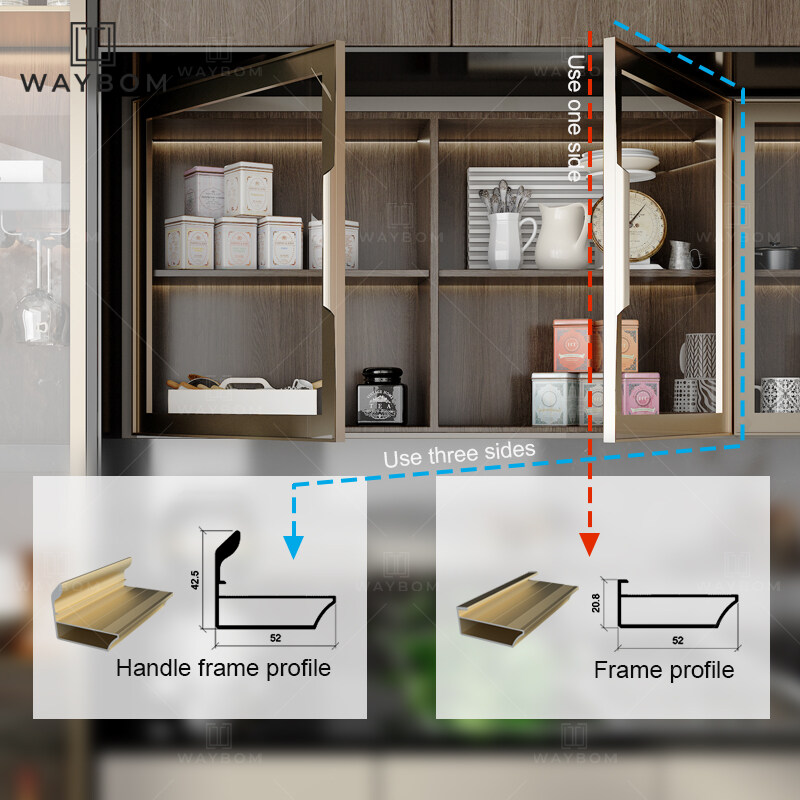

Luxury wide aluminium edge trim profiles for glass panel slim cabinet door

The light weight of the aluminum door panel is only 1/70 of that for bricks and 1/3 of that for stainless steel. The excellent rigidity and strength of aluminum are well-suited to form a high, stable wind load impact resistance frame.

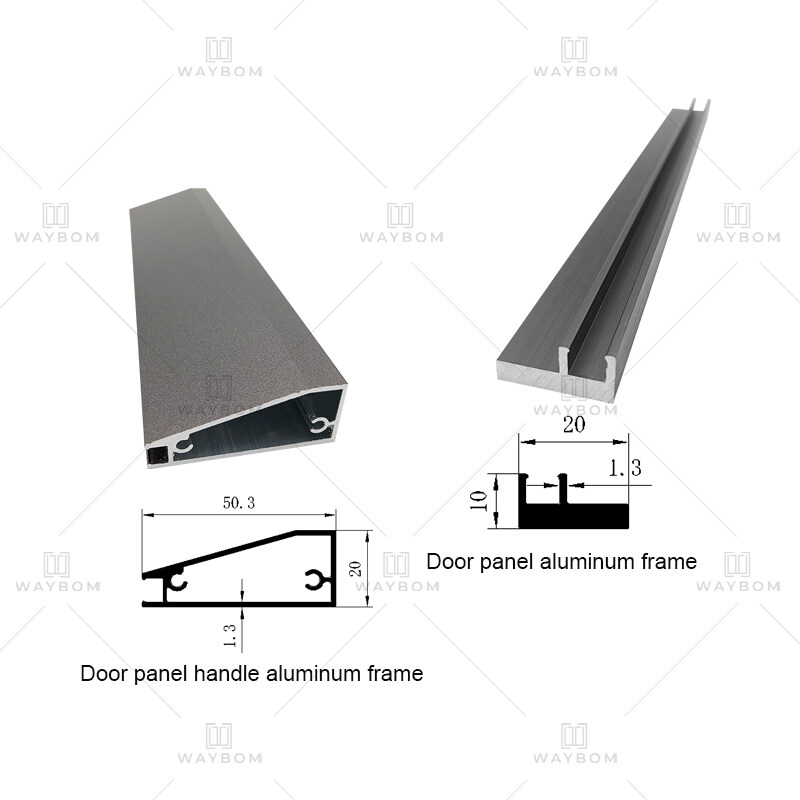

Product Description of Aluminium Edge Trim Frame Profiles for Glass Panel

The use of glass panels in modern architecture has been on the rise for the past few decades. Glass panels are used in buildings to create a sense of openness and allow natural light to enter the space. However, the edges of glass panels can be sharp and unattractive, which is why aluminium edge trim profiles are used to give the glass a clean and finished look.

Product Features of Aluminium Edge Trim Frame Profiles for Glass Panel

The aluminium edge trim frame profiles for glass panels have the following features:

- Lightweight, good rigidity, high strength, and safety.

- The weight of the aluminium door panel is only 1/70th of that of bricks and 1/3rd of that of stainless steel.

Product Advantages of Aluminium Edge Trim Frame Profiles for Glass Panel

Fireproofing Properties

The properties of aluminium door panels have been tested by the National Research Centre of Testing Techniques for Building Materials and meet the requirement for non-flammable materials. As per the GB-8624-1997 Standard, the fireproofing grade of aluminium door panels is GB-8624-B1.

Sound Insulation, Heat Insulation, and Heat Preservation

The cells between the two skins provide sound and heat insulation.

Moisture Resistance and Corrosion Resistance

The aluminium door panel surface skins are anti-anodizing, color-stable, and resistant to mold and deformation.

Environmentally Friendly

Aluminium single-solid panels can be recycled, and aluminium door panels do not emit any hazardous gases.

Door Panel Cleaning

Soluble cleaners should not be used for painted door panels, and all benzene-based and plastic-based solvents should not be used as panel cleaners. After cleaning, wipe off the moisture from the door panel and countertop with a dry fibre cloth.

Maintenance of Door Panels

The maintenance and cleaning of the cabinet door panel are similar to those of the countertop. Avoid water accumulation, placing heavy items, and high temperatures. Clean oil in time. If the door hinges and handles are loose or have abnormal noises, adjust them in time or notify the manufacturer for maintenance. Solid wood door panels can be cleaned and maintained with furniture water wax, while crystal door panels can be wiped with a velvet cloth dampened with water or neutral detergent.

Maintaining and cleaning the cabinets is simple. Avoid water accumulation, placing heavy items, high temperatures, and clean oil in time.

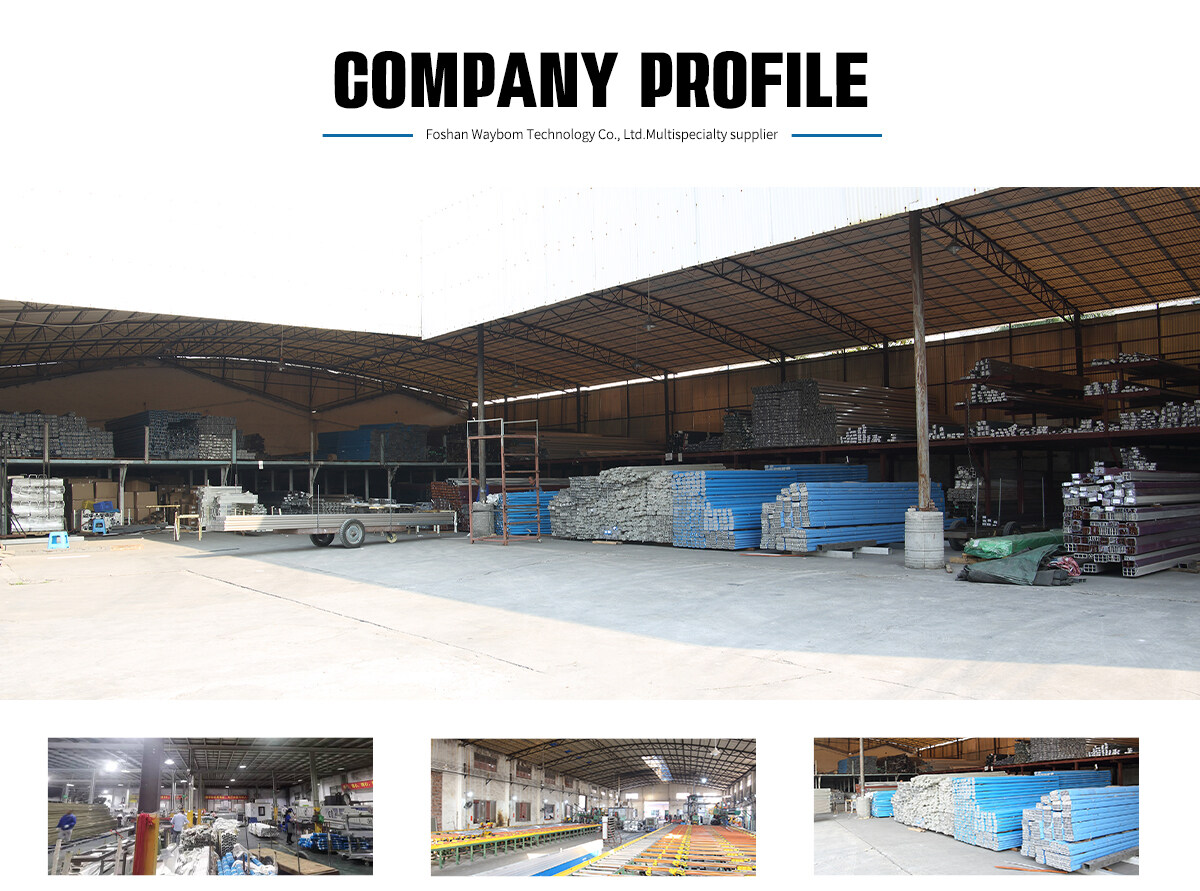

Our factory was established in 2008, covers an area of 56,368 square meters, has 176 employees. With 5 aluminum production lines, 20 CNC machining centers, 2 powder coating lines, several anodizing tanks, Polishing, brushing and sand blasting equipments, Well-established packaging and quality inspection system, our annual output of aluminum is 15000 tons, and more than 20,000 sets of finished products. We can satisfy your demands quickly from our stock or produce your own design. We do ODM and OEM.

We choose A0 degree aluminum ingot as raw material.

The most used 6063-T5 and 6061-T6 aluminum alloy comply with national standards GB/T5237.

We do extruding with designed moulds to get different shape of profiles.

The strength and toughness of the profiles are ensured by aging treatments.

Surface treatment like powder coating, anodizing and electrophosis are required to protect the profile and get good-looking surface.

We do offer machining services like milling, drilling, bending, threading, etc.

All products will be inspected strictly before packing.

After you place your order, we will check again and suggest you the best packaging method based on different shapes of products (including but not limited to kraft paper packaging/bubble wrap/wooden box packaging).

We provide different packages for different products to make sure the goods can stay good during long-time shipping. And we can do customization according to your requirement.

Usually we will use kraft paper, bubble wrap, plastic protective film, cartons, wood crate and pallet, ect.

Usually we need 15-45 days for production, and we would communicate with customers about all details for shipping a week earlier before goods are ready.

Either you have shipping agents or not, we can assist you to ship the goods and provide you documents for custom clearance. And door to door shipping is also available.